NOVAIR, is a medical gas specialist since 1977 and a world leader in the design and manufacture of PSA medical oxygen generators. Through its complete range OXYPLUS at the forefront of innovation, the Group designs and manufactures in France on site oxygen production solutions exclusively dedicated to supplying the medical gas network of hospitals and clinics, and adapted to healthcare facilities of all sizes.

OXYPLUS oxygen generators offer exclusive guarantees of oxygen purity. In addition, only NOVAIR offers in its range a generator able to produce 99.5% pure oxygen.

Our range of medical oxygen generators

99,5% – Ultra High Purity DS-PSA Oxygen Generator

PREMIUM +PLUS

Oxyplus Technologies introduces Premium Plus, ultimate development in the world of PSA oxygen generators.

PREMIUM PLUS is the ultimate development in the world of medical oxygen generators. Equipped with innovative technology, it combines cutting-edge performance and design to deliver the high concentration medical oxygen of your choice, with an exceptional stability.

- DS-PSA Technology : 96-99.5% oxygen purity

- Oxygen Concentration Stabilizer OCS

- Control panel with15″ colour touch-screen

- Lateral panel for oxygen analyzer calibration

- Up to 99.5% oxygen purity

- Ultra stable concentration : +/- 0.2%

- Adjustable purity on-site by end-user

- User friendly & easy to maintain

95% – Twin Tower PSA Oxygen Generator

PREMIUM

OXYPLUS Technologies PREMIUM oxygen generators provide outstanding efficiency and reliability. Designed for hospitals with surgical activities and intensive care units, they produce a high and stable medical oxygen quality at 95% +/- 1%.

- High and stable oxygen concentration

- Fully automatic operation 24h/24

- Touch screen control panel

- Remotely manageable

VisiO2 is an advanced control device which automatically manages and monitors the oxygen generator operation. It features an HD colour touch screen to display and control the production parameters. It provides real time curve drawing, alarms management and archiving, remote alarm transfer and automatic permutation for installations with two oxygen generators. With its recording capability, VISIO2 provides healthcare facilities a complete traceability and continuous quality control of the oxygen produced.

95% – Modular PSA Oxygen Generator

OXYSWING

OXYSWING® is a modular PSA oxygen generator range. Unlike twin-tower standard systems, OXYSWING® generators feature multiple modules of molecular sieve. This optimized patented PSA process provides high flexibility of use and easy adjustment to the required flow.

Production capacity can be easily adjusted directly on site by simply adding modules without any requirement of skilled personnel

For large capacities, OXYSWING® generators can be completed with a Dual Bank, wich consist in a second PSA oxygen generator without any PLC and power supply.

It allows the monitoring / remote control of the main process parameters and displays status messages such as gas purity and flow rate, totalized gas flow, total functioning hours and maintenance alerts.

93% – Twin Tower PSA Oxygen Generator

ORLANE

ORLANE oxygen generators guarantee at the most competitive cost a medical oxygen production on-site at 93% +/- 3% purity level that is in full accordance with the European and US Pharmacopeia. They particularly meet the needs of healthcare facilities looking for autonomy while facing strong budgetary constraints.

- Oxygen quality compliant with the pharmacopeia

- Fully automatic operation

- On-site oxygen production at a competitive cost

Supplied on a turnkey basis, the ORLANE skid is very compact and allows an easy installation on site. The whole device is preassembled on the skid allowing a quick installation, start-up and commissioning – generally between 48 and 72 hours.

ORLANE oxygen generators are automatically managed by their CPU control panel: based on a PLC system, it includes a logic controller, a digital screen and an ergonomic control panel. Key information such as oxygen concentration, hour meter and alarm reports are displayed on the CPU screen.

93% – Compact and Mobile Oxygen Generator

MODUL O2

For healthcare facilities with little or no access to medical oxygen, or for a back-up supply in operation theaters and ICUs, OXYPLUS Technologies has designed ModulO2, the most user-friendly and high perofrming compact oxygen generator, designed to supply a 93% oxygen with a pressure of 3.8 bar.

- Plug & Play oxygen generator

- Compact, mobile and silent

- 10 to 20l / min flow at 3.8 bar

- Integrated PSA columns

- Integrated oxygen analyzer

- Fully automatic

- Oxygen supply for a small healthcare facility piping network

- Oxygen supply for an anaesthesia machine in an Operating Theater (OR)

- Oxygen supply for a ventilator in an intensive Care Unit (ICU)

- Oxygen supply for patients under oxygen therapy

- Oxygen supply for a high pressure cylinder filling system

Medical air production

What is medical air?

Medical air is a gas for medical use mainly used for:

- Aerosol therapy and ventilator therapies

- Inhalation anesthesia

- As an alternative to supplemental oxygen

- Drying medical equipment

- The operation of surgical instruments

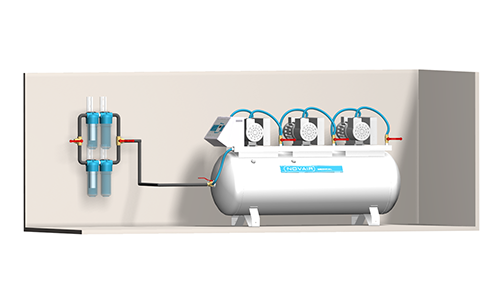

Medical air stations

NOVAIR Medical air units are medical devices marked “CE – Medical Device” class IIa, according to the European directive 93/42/CEE. They are designed in accordance with French and European standards.

All medical air stations are composed of :

- a single, double, triple and even quadruple air production in accordance with the configuration required and local standards

- a control box ensuring also the regulation alarm reporting and management.

- a compressed air receiver

- a single or double refrigeration or adsorption air treatment chain

- a medical air receiver “homogenizer”

Lubricated screw

Screw air compressors

NOVAIR offers a range of lubricated screw air compressors designed to ensure the production of compressed air with an optimized energy consumption. Available with an electronic control system, they are particularly robust.

NOVAIR lubricated screw medical air systems are composed of 1 to 4 soundproof screw compressors. Each compressor operates alternatively, in order to balance the running time per machine.

- Power : 5.5 to 110 kW

- Flow : 16 to 978 m3/h

- Pressure : 7 to 13 bar

Pistons

Pistons medical air compressors

The piston technology is widely used in healthcare facilities and has proven its efficiency and reliability over time. NOVAIR pistons compressed air systems are available in lubricated or oil free versions and require simple maintenance. Preferably meant for low capacity.

NOVAIR pistons medical air systems range includes simple, double and triple versions. Each compressor comes with 2 lubricated or oil free pistons, v shape mounted.

- Power : 0.75 to 7.5 kW

- Flow : 4 à 56 m3/h

- Pressure : 4 to 15 bar

Scroll

SCROLL air compressors

Ensuring the production of compressed air without oil, NOVAIR SC compressors are designed to operate at full capacity with low maintenance costs and a high reliability. Responds to the needs of healthcare facilities looking for oil free solutions.

SCROLL medical air systems feature a multi scroll cabinet designed to house up to 3 compressors.

- Power : 2×5,5 to 3×7.5 kW

- Flow : 53 to 153m3/h

- Pressure : 8 or 10 bar

Our technical department can help you to define the configuration and model of air medical station the most adapted to your healthcare facility.

We design also tailored stations to meet specific issues of our customers.

Medical vacuum production

What is medical vacuum?

Medical vacuum is a dedicated to :

- Ensure the surgical drainage of pleural or pericardial effusions for example

- Declutter the airways or gastric patients by aspiration

NOVAIR Medical Vacuum Systems are designed for the central supply of medical vacuum in hospitals/clinics,

and in particular in ICU, emergency departments as well as operating theaters.

Technology & design

NOVAIR has been supplying Medical Vacuum Systems to hospitals and clinics around the world for over 40 years. Featuring high efficiency lubricated or oil free rotary vanes pumps, they come in various available configurations to suit the needs of all healthcare facilities :

- Compact horizontal: integrated on horizontal receiver

- Compact vertical: integrated on a vertical steel frame

- Modular: separated modules to fit specific requirements

- In skids or shelters, according to customers’ specification

NOVAIR medical vacuum systems are composed of :

- a single, double, triple and even quadruple vacuum pump in accordance with the configuration required and local standards

- a PED certified tank with equipment

- a CPU control box

- interconnexions

- an antibacterial filtration

Key features :

- Medical Device CE class IIa

- Fully automatic operation by CPU controller

- Non lubricated version available upon request

Anesthetic gas scavengers stations (AGSS)

NOVAIR Medical AGSS systems ensure the elimination of all residual anesthetic gases within the operating theater or the recovery room, protecting medical staff from potentially hazardous exposure to those gases.

With capacities up to 2×250 m3/h, NOVAIR AGSS solutions cover the needs of all types of healthcare facilities, in accordance with all current regulatory standards. We also design tailored systems to meet specific needs to our customers. Our technical department is at your disposal to help you define the configuration and model of specifical vacuum station the most suitable for your healthcare facility.

High pressure cylinder filling systems

Cylinder filling of 10 to 100 medical oxygen cylinders a day*

NOVAIR Medical offers a full range of high pressure cylinder filling systems allowing to fill daily 10 to 100 medical oxygen cylinders at a pressure of 150 to 200 bar.

Designed to be connected to a NOVAIR oxygen generator, the systems provide full autonomy to healthcare facilities : they can easily manage peak consumption flows and fill their own cylinders.

*also available for air

Benefits

- 100% oil free high pressure booster

- Full autonomy : designed to fill back up cylinders on site

- Long service life (low RPM)

- Heavy duty design for continuous operation (24h/7)

- CPU controller smart monitoring system for HP45 to HP360

Container or Skid

OXYFACTORY, an autonomous and continuous oxygen, air or vacuum production on-site for your healthcare facilities

OXYFACTORY production cabins and skids from NOVAIR Medical provide an autonomous technical room dedicated to the production of medical oxygen, air or vacuum, without any change to the inner structure of your healthcare facility.

Our production systems are fully pre-assembled, wired and tested at our plants. They are supplied ready to be connected to power grids and facility gas network.

Production cabins and containers are fully equipped to ensure an optimal operation and zero annoyance to the healthcare facility environment : sound and heat insulation, air conditioning, hot air extraction cases, heat, general switch cabinet…

Cabins and containers are easily transportable by truck and are available in “maritime” version.